Composite Manufacturing

Composite Manufacturing with Infrared Heating

The world of composite manufacturing is constantly seeking faster, more efficient, and more cost-effective methods. Infrared (IR) heating technology has emerged as a game-changer, offering significant advantages over traditional methods in various stages of the manufacturing process.

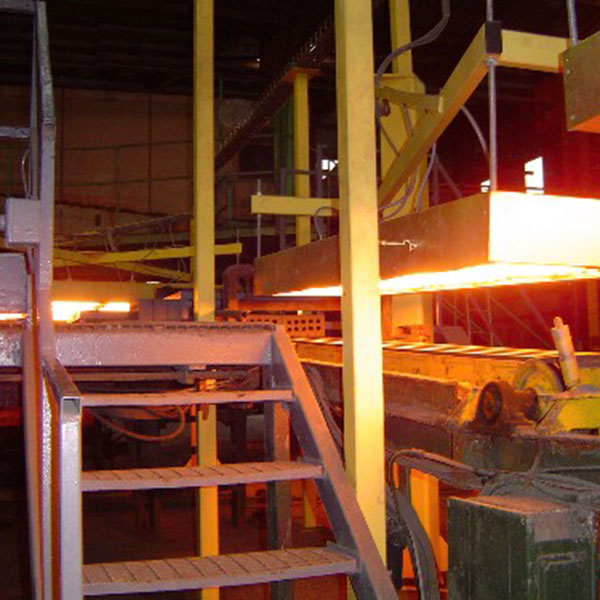

Infrared Heating in Thermoplsatic Composite Sheet Forming

In sheet forming, a sheet of solid composite laminate is rapidly heated by infrared emitters and subsequently formed by pressing between two cooler tools. This process, enabled by IR heating, is characterized by remarkably fast cycle times, a crucial factor in boosting productivity. The precise and rapid heating provided by IR allows for quicker processing and shorter lead times compared to traditional methods.

Infrared Heating for Enhanced Resin Curing

For the three main types of heat-curing resins used in composite manufacturing (epoxy, phenol formaldehyde, and urethane), IR heating offers substantial improvements. It provides faster heating times, reduces the required oven length, and significantly increases line speed compared to conventional convective heating ovens. This translates directly to increased production capacity and reduced operational costs.

Precision and Control in Tape Laying with Infrared Technology

Infrared heating also plays a vital role in tape laying, a process where “tape” of raw material is heated and deposited onto a former. A high-watt density infrared lamp, such as a quartz tube, precisely heats the area ahead of the tape deposition. This precise heating, combined with robotically controlled heads, ensures high repeatability and exceptional control, leading to superior product quality and consistency. This technology is used in the production of several components on aircraft such as the Airbus A400M and A340, highlighting its effectiveness in high-precision composite manufacturing.

Advantagees of IR Heating

The benefits of employing infrared heating in composite manufacturing are numerous:

- Rapid Heating and Cooling: Significantly faster processing times compared to conventional methods.

- Targeted Heating: Precise control over the heating zone, reducing energy waste and improving efficiency.

- High-Watt Density: High-intensity heating for faster processing, suitable for high-volume production.

- Increased Production Speeds: Leads to higher output and greater profitability.

- Compact Installations: Reduces the footprint required for equipment, saving valuable space.

- Lower Investment Costs: Compared to some traditional methods, infrared systems offer a lower initial investment.

- Adaptability and Expandability: Easily adaptable to different applications and scalable for future growth.

- Essential for Specific Repairs: Often the only practical solution for certain types of composite repairs.

- Volumetric Heating: Penetrates polymers, providing more even heating than surface-based methods.