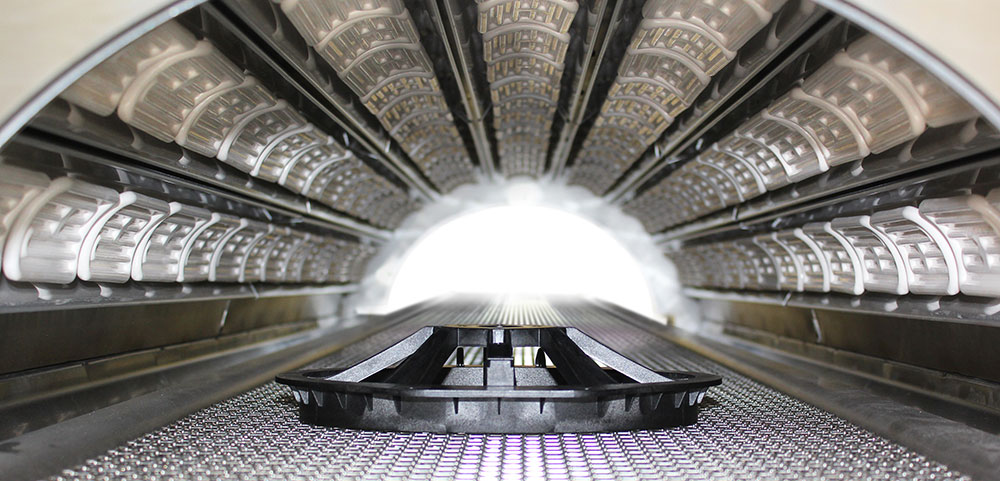

High Speed Plastics Thermoforming Oven Solutions

Creating the Finished Package

WECO uses infrared heaters that increase thermoforming efficiency and make thermoforming profitable for you. An Industrial thermoforming oven can be used for heating sheets of composites and thermoplastics to a high temperature so they can be stretched and molded into a shape. Thermoforming ovens are perfect for pre-heating, with suitable heating technology for a tension-free, flawless heating process. WECO thermoforming solutions are typically supplied as a retrofit heat system for production lines making Fast Moving Consumer Goods (FMCG).

The popularity of the our infrared solutions are growing, since average energy savings of 40% along with up to 20% productivity improvement are possible and payback time is measured in months. WECO thermoforming ovens are custom designed for each unique application.

The plastics thermoforming industry is often accused of being energy intensive and inaccurate compared to plastics injection molding but WECO industrial heat consultants have the expertise to supply thermoforming replacement heaters to thousands of thermoformers worldwide – saving the industry millions and improving thermoforming line efficiency in the process.

Thermoforming Heating Control System Benefits:

- Major reduction in capital equipment wear and tear

- Like-for-like infrared for tubular replacements

- Elimination of ‘hot box’ tubular problems

- No need for changes in control or instrumentation

- Poor performing infrared to be replaced with superior platens

- Savings in directional heat

- Better resulting product quality

- Improved set-up time and tool change time

- More complex parts possible

- Cooling requirements also reduced

- Matching of heating control systems to polymers being processed

- Improved environment for operators

Industrial Thermoforming Oven Applications:

- Aerospace composite press forming

- Automotive fuel line heat setting

- Thermoplastics press forming

- Automotive headliner forming

- Skylight acrylics

- Composite deck board embossing

- Glass forming

- Aluminum sheet forming

- Batch and Conveyor Systems

- Interior components forming

- Packaging forming

- Fiberglass forms

- Foam Speaker forming