Composite Forming

Heat Meets Pressure to Transform Composites

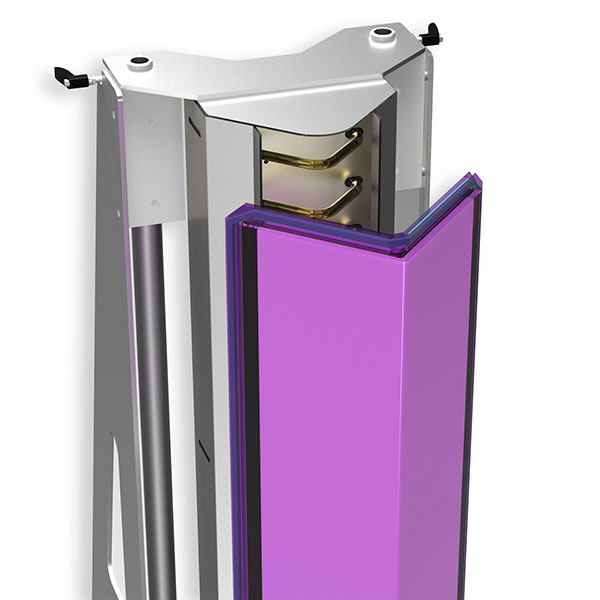

WECO International has a number of solutions to offer in the area of composites thermoforming. Each composite material formulation will vary from client to client and our engineers are here to provide you with the correct solution for your needs. Our oven testing services enable full testing of each heat and material interface. We can help take 3D measurements and maps of the forming process under infrared heat before machine build takes place. WECO designs and builds composites thermoforming ovens for its customers, each specific and customized for particular materials

Thermoforming heating control systems produces a host of other benefits, including:

- Major reduction in capital equipment wear and tear

- Like-for-like infrared for tubular replacements

- Elimination of ‘hot box’ tubular problems

- No need for changes in control or instrumentation

- Poor performing infrared to be replaced with superior platens

- Savings in directional heat

- Better resultant product quality

- Improved set up time and tool change time

- More complex parts possible

- Cooling requirements also reduced

- Matching of heating control systems to polymers being processed

- Improved environment for operators