Finishing and Curing Ovens

More Than Drying Products

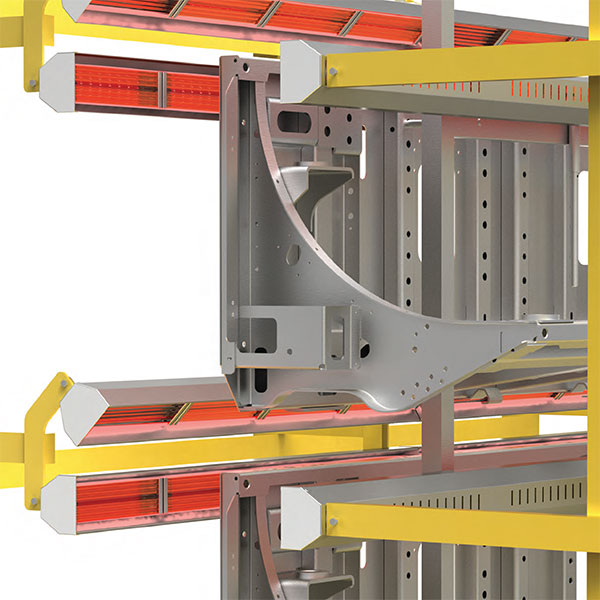

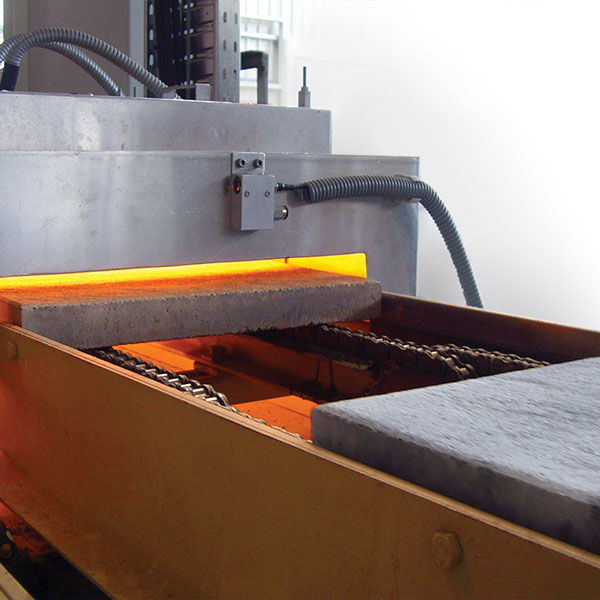

WECO International designs systems and production lines for manufactured products’ infrared drying using custom-made curing ovens. Our systems often involve the complex interaction of paints, polymers, and inks, with substrates of plastics, metals, stone and concrete, papers, and other products. Infrared drying systems typically involve pre-drying stages and sophisticated patterns of heat control, together with a ‘deeper’ heat exchange and subsequent chemical/bonding reaction. Infrared heat drying can provide many manufactured products with a more lasting and quality finish.

In the realm of drying and curing applications, infrared curing ovens stand out as a cutting-edge solution that offers unparalleled efficiency and precision. At WECO International, we take pride in delivering state-of-the-art technology to enhance your drying processes. Our infrared curing ovens utilize advanced infrared radiation to ensure rapid and uniform curing of coatings, paints, and adhesives. This innovative technology accelerates the drying process, resulting in higher throughput and reduced energy consumption.

WECO engineers design infrared heating systems for:

○ Final stage production processes; finishing and drying of products.

○ Greater process precision – ensuring a quality finish to many products

Experience the future of drying and curing with WECO International’s cutting-edge infrared curing ovens. Maximize productivity, reduce energy costs, and elevate the quality of your finished products with our advanced technology. Explore the possibilities and stay ahead of the competition with our innovative solutions for your drying and curing needs. Contact us today, we’re ready to talk about your project.