Composite Molding

Molding Components for Trains, Boats and Planes

Our industrial heat consultants are seeing great growth in demand for its infrared heat in manufacturing and its IR heating work in composites for manufacturing.

Light-weighting of traditional products and components in all kinds of industries – especially transport – is now a key part of our energy-conscious future. Composite materials of all kinds have a key part to play and it includes uses such as composite polymer molding and reinforced plastic molding.

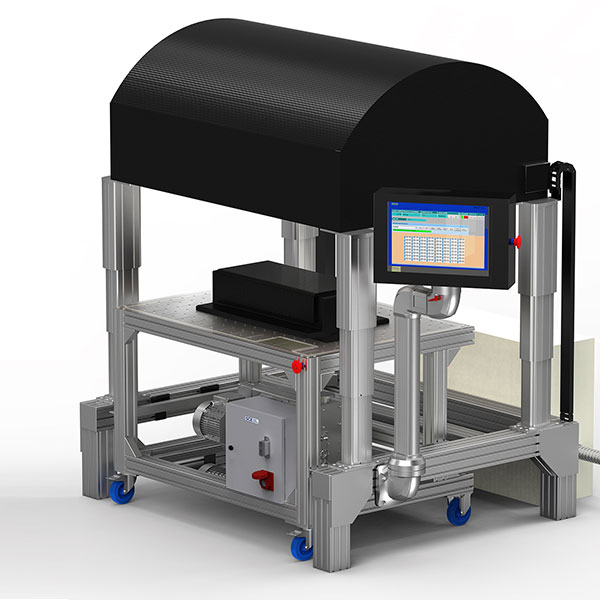

WECO International is playing its part by working with composites companies to design optimum ways of heat forming and processing these innovative materials – through autoclave, oven design and other IR heat drying methods.