The Main Types of Infrared Heat Emitters

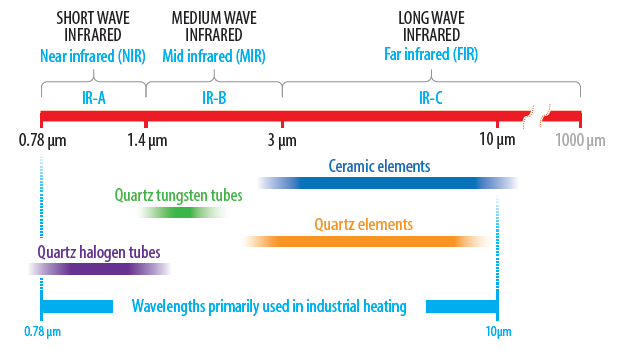

Infrared heat emitters used in industrial heating have a usable peak emission wavelength ranging from 0.75 to 10 µm. Within this range, there are three subdivisions. Those subdivisions are long, medium and short wave.

Long wave emitters, also known as far infrared (FIR), have a peak emission range in the 3-10 µm range. This range generally refers to ceramic elements which consist of a FeCrAl resistance coil embedded into either a solid or hollow constructed, highly emissive ceramic body. Ceramic emitters are manufactured by Ceramicx in a number of industry standard sizes with either flat or curved (trough style) emitting surfaces.

At the shorter end of the medium wave range is the quartz tungsten infrared emitter. This consists of a sealed linear clear quartz tube containing a star design tungsten coil. The tungsten coil provides a fast response time with low thermal inertia. At the shorter end of the spectrum lies the short wave halogen range. The basic construction is similar to that of the fast medium wave tungsten emitter with the exception that a round tungsten coil is used instead. The higher coil temperature results in the generation of white light and a peak emission wavelength in the short wave range.

Ceramic Elements 2 to 10 µm

Quartz Elements 1.5 to 8 µm

Quartz Tungsten Tubes 1.6 to 2 µm

Quartz Halogen Tubes 1.0 to 1.4 μm