Beverage Manufacturing Innovation Clamshell Oven for Curing

When you need 360 degrees of heats a custom infrared clamshell oven for curing with quartz halogen tubes is the solution. Quickly and precisely cure the outside layer of a synthetic material used it the drinks industry.Read More

Infrared Curing Oven for Foam on Speakers

The system was designed to cure foam on the back outer edge of polycarbonate speaker baskets at an accelerated time rate. The system consists of 4 primary components: The infrared oven, conveyor 1 ( load conveyor ), conveyor 2 ( unload conveyor ) and a control panel.Read More

Efficient Preheat Oven For Polyethylene Embossing

Custom industrial infrared oven for a food packaging film supplier to preheat polyethylene film prior to an embossing operation. Improved start up times and line speed from the innovative use of flat square hollow elements and reflectors.Read More

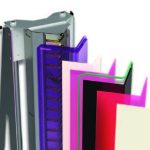

Thermoforming Heating System Upgrade

A tier 1 automotive supplier needed uniformity of heat to ensure repeatability and consistency of product. WECO designed and built a top and bottom infrared heating system using HTE long wave ceramic heaters.Read More

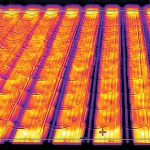

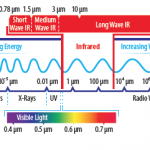

The Infrared Curing of Carbon Composites

Ceramicx never tires of preaching the fundamentals of Infrared’s Heating characteristics and effects. November, 2017, Dr Peter Marshall of Ceramicx took the opportunity to brief …Read More

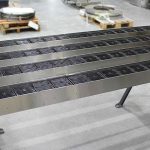

Putting Composite Curing to the Test

Infrared heat sources reduce energy waste in composite curing. Companies realized the potential of infrared (IR) for a long time, having undertaken initial research into physical properties such as tensile strength, three point bending, impact resistance and other factors key to validating composite curing methods.Read More