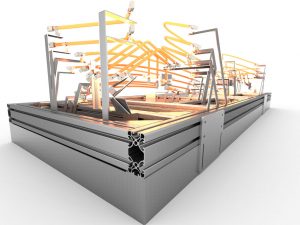

Energy Efficient Custom Infrared Ovens

WECO can test your material and recommend the most energy efficient industrial heaters, custom infrared ovens and processing solution for your application. Whether you are manufacturing anything from aerospace to automotive to food. We build fully automated systems such as conveyor systems by incorporating a multitude of sensors and integrating state of the art control systems. Our ovens can operate stand alone or be integrated into an existing line.

We handle applications as large as swimming pools and as small as a contact lens.

Ceramic Infrared Ovens

These custom infrared ovens, suitable for infrared furnace ovens or conveyor ovens, are designed with your market in mind. The available variations in platen size and element type depend on the area to be heated and the application or target material involved. We can test your material and recommend the most energy efficient industrial heaters and processing solution for your application.

- X” x Y” heated area.

- X heaters per zone for X zones of control, customer specific.

- “Intelligent Infrared” uses highly efficient elements and unlimited zone control options to minimize energy usage, maximize production, and reduce scrap.

- Mounting brackets as required to match existing mounting provisions.

- Each heater wired back to terminal junction box on end of oven frame.

- Optional pre-wired quick connect system.

- Drawings and documentation for custom infrared ovens are included.

Quartz Ovens

Quartz infrared heating elements provide medium wave infrared radiation. Industrial applications favor them in situations requiring a faster heater response, including systems with long heater off cycles.

- Quartz infrared heating elements are particularly effective in systems where rapid heater response and/or zone controlled heating is required.

- They have a broad emission spectrum from around 1.4 to 8 microns, slightly shorter in wavelength than ceramic elements.

- Pillared quartz elements have the same mounting fixture as ceramic elements allowing easy replacement.

- This easy change pillar is ideal for design alterations involving the use of materials with different absorption characteristics.

Halogen / Tungsten Ovens

IR heat technology has several possible roles to play in manufacturing; in the drying, bonding, and annealing of various materials and components, and in the production of various parts and structures. Increasingly WECO designs and builds IR ovens – drape forming or thermoforming – for production of larger parts.

- Quartz Tungsten and Halogen fast response (obtains top temperatures in seconds), high intensity tungsten filament heating lamps emit medium to shortwave infrared radiation.

- Built into special heat reflector systems, the emitters in these infrared ovens allow instant heat, precise control and very effective directional heating.

- The tungsten filament used in Quartz Tungsten ir heat emitter is the porcupine or star type coil, which can be operated at temperatures up to 1500°C (2732°F), with peak wavelength emissions of approximately 1.6 microns. To enhance IR radiant efficiency, this coil is designed with excellent structural rigidity to minimize light output and maximize IR emission.

- Quartz Halogen emitters contain Halogen gas to enable the supported tungsten filament to reach temperatures as high as 2600°C (4712°F). The emitter has peak wavelength emissions of approximately 1 micron, are extremely penetrative, and allow rapid on/off cycles.

Options:

- Lead Styles:

- R7s or various lead lengths

- Quartz Tungsten Elements:

- QTL – Quartz Tungsten Long Emitter

- QTM – Quartz Tungsten Medium Emitter

- QTS – Quartz Tungsten Short Emitter

- Pillared Elements:

- QHL – Quartz Halogen Long Emitter

- QHM – Quartz Halogen Medium Emitter

- QHS – Quartz Halogen Short Emitter