Process Industries

Infrared Heat Conversion For The World’s Process Industries

Process industries convert raw materials such as foodstuffs, chemicals, pharmaceuticals and polymers into usable products.

Production is generally continuous and relevant factors are typically ingredients and bulk materials rather than individual units. A borderline area would be the work involved in composite structure manufacturing from ovens or cut sheet thermoforming operations.

IR heating both catalyzes and improves the heat work involved in the world’s process industries. Time is of the essence in manufacturing and IR heat sources generally reduce cycle time; bringing materials to the required transitional states much more quickly and effectively than alternative energy sources.

The IR heat flux also offers a much more effective and penetrative rate of heat transfer than alternatives, again saving time and therefore cost.

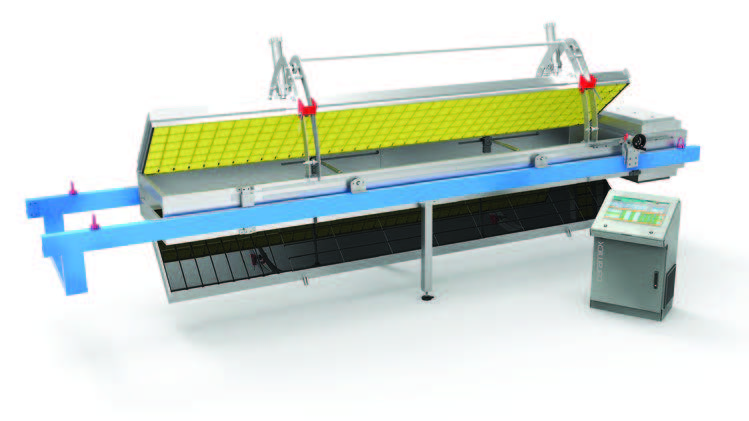

The IR heat is generally delivered via a variety of specially designed ovens, heating platens and furnaces types for the heating and transformation of foods, chemicals and polymer types of all kinds.

IR heat sources are favored by the world’s process industries not only for their manufacturing effectiveness but also for their clean and green properties.

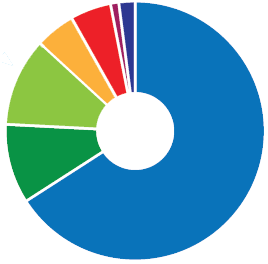

Typical Energy Cost in a Polymer Processing Site

“What is your energy cost? Have you measured? To measure is to manage.”

| Plastics Processing 66% | |

| Compressed air 10% | |

| Chillers 11% | |

| Water pumps 5% | |

| Lighting 5% | |

| Offices 1% | |

| Heating 2% |