Thermoforming Ovens Upgrade for Custom Appliance Maker Case Study

Supplier: WECO International

Client: Custom Commercial & Consumer Appliance Manufacturer

Industry: Home & Commercial Appliances

Location: North America

Opportunity:

Our client was struggling with outdated and inefficient thermoforming ovens, posing a drag on their quality and productivity. A new platen system with zone-specific heating controls and energy smart technology was the best course of action to solve the issues at hand while giving the client the greatest options to hone production.

Client Challenge:

The custom-appliance business is exacting, requiring the goods from our client to look great and hold up against anything that may come along. Products rolling off their lines are the centerpieces in high-end homes and intense commercial kitchens.

Having found several key issues, our client opted to replace several machines in their thermoforming production line. As forerunners in ceramic and infrared heating, WECO International came onboard to provide the necessary equipment and expertise.

A badly outdated oven system with a patchwork of third-party elements was stretched to capacity under the simplest of demands. Beyond the mismatched heat emitters, the lack of zone controls hindered production and wasted energy. Boosting production efficiency metrics while lowering costs was essential to this project.

Our Solution:

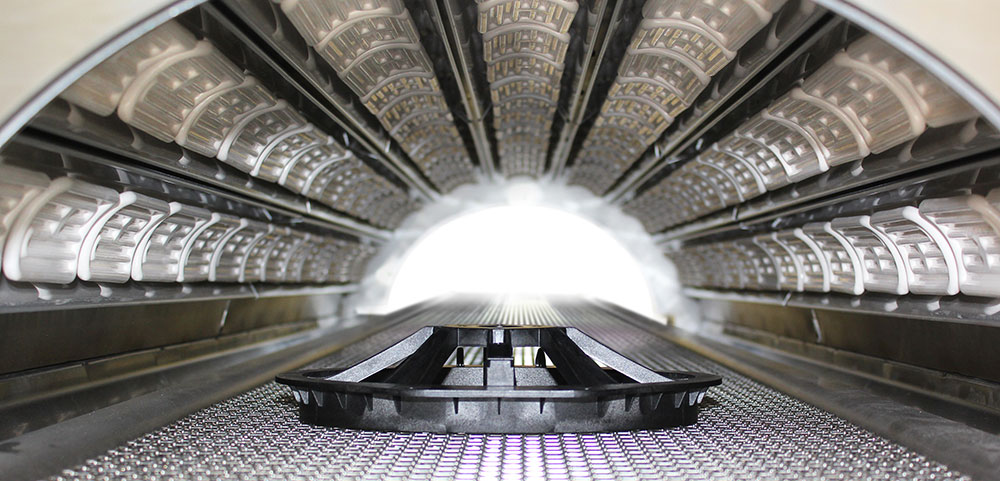

After examining our clients needs, WECO International settled on a complete overhaul of the prior systems. First came a complete teardown and removal of the old ovens and controls. From there, a tailor made “Rotary Machine” thermoforming oven, featuring high-temperature Ceramicx infrared heating elements, was installed. This built-to-suit system with high-temperature heat emitters was paired to a one-off Ethernet-enabled multi-channel heat controller with multi-zone capabilities for seamless production integration. The variable-zone platen management system, built by experts at WECO International, ushered in a high versatility for both temperature control and energy management. Their prior thermoforming oven afforded them no such comfort, and had no control capabilities beyond powering on and powering off.

Outcome:

Following the completion of this project, our client has seen increases in the quality and quantity of their production output. WECO International appreciates the need of all clients to overcome production obstacles, and their drive to surpass existing standards for material finished goods. This project is another example of the holistic approach we take when examining any job.

Following the debut of the new thermo-forming system, our client saw an immediate boost in production using our custom industrial oven system. Furthermore, they can track the performance of this system in all areas of use, from furnace efficiency to energy consumption, thanks to the Ethernet-equipped controls module. That level of specific fine-tuning is something most companies only dream about, while our client can adjust this system in real-time.

At WECO International, we’re about more than just brass-tacks. We work for complete client satisfaction with the quality and support we provide. We’re happy to say that this was another job well-done! While specific details could not be provided, our client reported increases in both the quantity and quality of finished goods. Similarly, the new machinery yielded considerable cost-savings advantages in reducing energy waste and managing the supply of valuable raw materials.