Thermoforming Heating System Upgrade

Supplier: Ceramicx

Client: Tier 1 automotive supplier

Industry: Automotive

Location: Europe

Opportunity:

This client was struggling with an outdated and inconsistent thermoforming heating system. Ceramicx has the technology needed to provide the client with a new up-to-date system that can produce the same product every time while also improving quality and productivity.

Client Challenge:

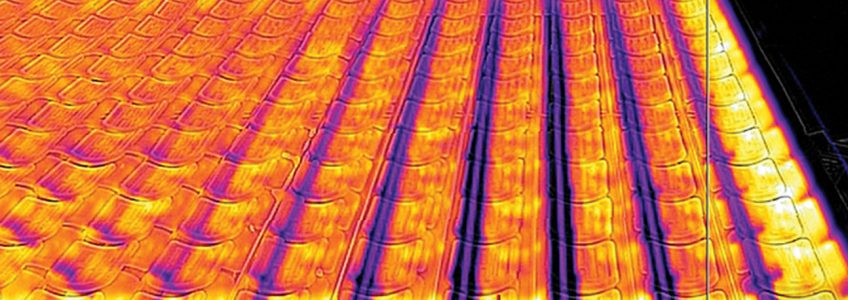

The client was having productivity issues. Specifically, they were looking for uniformity of heat to ensure repeatability and consistency of product. Quality and yield are two pillars of any manufacturing facility, therefore if they can be improved, the manufacturing site gains both in cost and morale.

Additionally, With the client being in the automotive business, it is important that their product comes out correct every time. With inconsistencies in heating, the client opted to have a new infrared thermoforming heating system custom built to the material, temperature, power, and time requirements of the process. Experts at Ceramicx were able to provide this solution with the best equipment.

Our Solution:

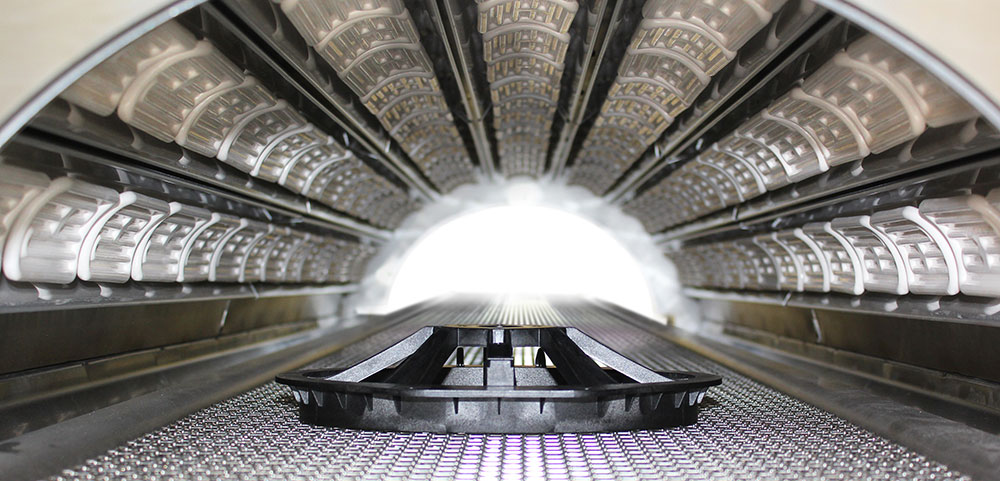

After knowing exactly what the client’s needs were, Ceramicx designed and built a top and bottom infrared heating system. They used HTE long wave ceramic heaters. A total of 18 zones of control were outlined by the customer, and a series of HTE 300W ceramic long wave heaters were used around the edge of each heating system to minimize edge loss. This new, fully customized system will save the supplier money in productivity.

Outcome:

With the new thermoforming heating system up and running, the client is able to produce more efficiently and keep a more consistent product. The new ceramic heaters are able to quickly get to their required temperature, which made the client happy. They were also impressed with how easily the IR heat emitters found and stayed at that required temperature set-point. Above all, The client can produce the product needed, worry-free. Ceramicx has since worked on another project with this supplier and supplied them with a second infrared heating system for a different manufacturing facility in the UK.