Infrared Curing Oven Provides Optimal and Uniform Foam Heating

Supplier: WECO International + Ceramicx

Client: Consumer Electronics Company

Industry: Electronics Manufacturing

Location: USA

Innovative Solution to Cure Curved Foam:

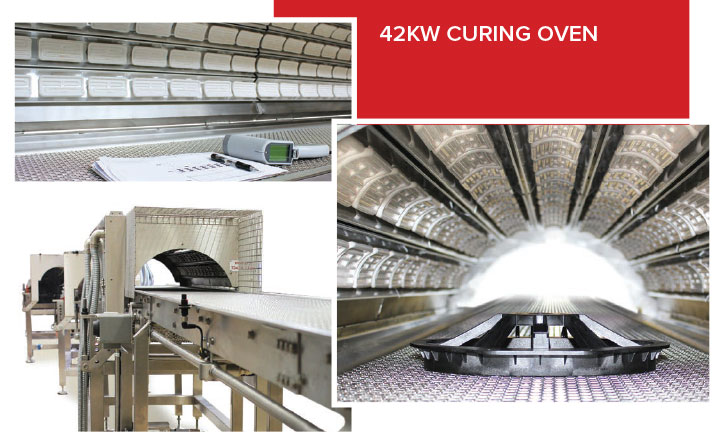

Finding the need to optimize production of their speaker line, a leading USA based consumer electronics company reached out to WECO International. The system was designed to cure foam on the back outer edge of polycarbonate speaker baskets at an accelerated time rate. Engineers designed a 42 kW infrared long-wave tunnel oven which was supplied in two sections.

Curved Infrared Heating Elements Ensure Optimal Heating:

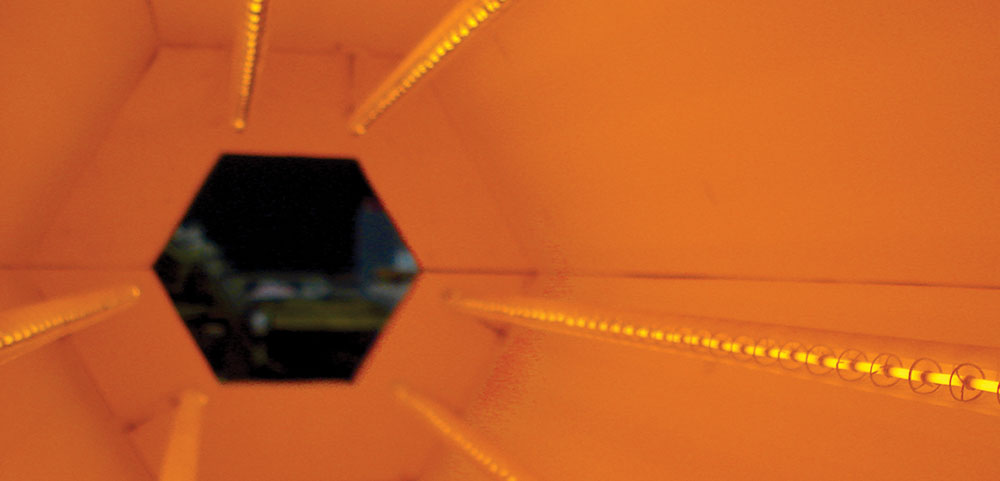

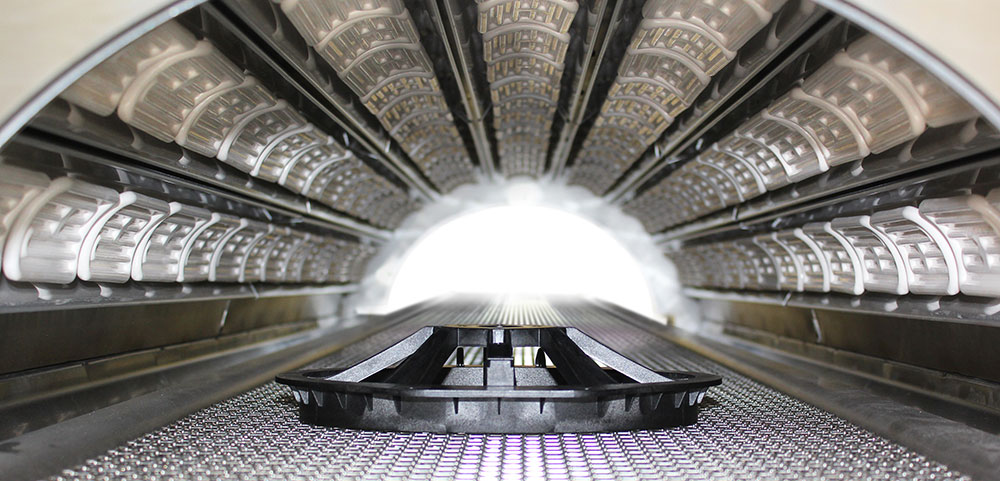

Ceramicx Long Wave Half Trough Elements (HTE) were used in the infrared curing oven to ensure optimal and uniform foam heating. These curved ceramic infrared heaters are an industry leading product. HTE type elements allow an increased number of zones within the oven for better temperature control.

The solid cast elements are used in a wide range of industrial, commercial and domestic applications. They consist of a high-temperature FeCrAL resistance alloy embedded in a specially formulated ceramic body. This allows operating temperatures up to 750°C. You can learn more about these elements by visiting our Infrared Ceramic Heating Elements page.

Multi-Zone Clamshell Infrared Oven With Conveyors:

Designed with the future in mind, a clamshell design makes it easy to access parts for replacement and maintenance. The system consists of 4 primary components: The infrared oven, conveyor 1 ( load conveyor ), conveyor 2 ( unload conveyor ) and a control panel. As is standard for Ceramicx and WECO ovens, the frameworks of all components (infrared oven and conveyor) were constructed with stainless steel.

Optimal Integrated Oven Controls:

The key to the state-of-the-art machinery was the Human Machine Interface (HMI) control system that allowed the conveyor speed as well as oven power could be controlled. The control type included a 24 zone closed loop control with embedded TC/K feedback for optimal performance.