WECO Client Case Studies

Following our slogan of “Putting the Pieces Together”, WECO integrates our products to provide new and retrofit oven assemblies and controls for a variety of infrared heating applications, including forming, curing, and drying. Check out the case studies below to see how we put the pieces together to create IR heating solutions for our customers.

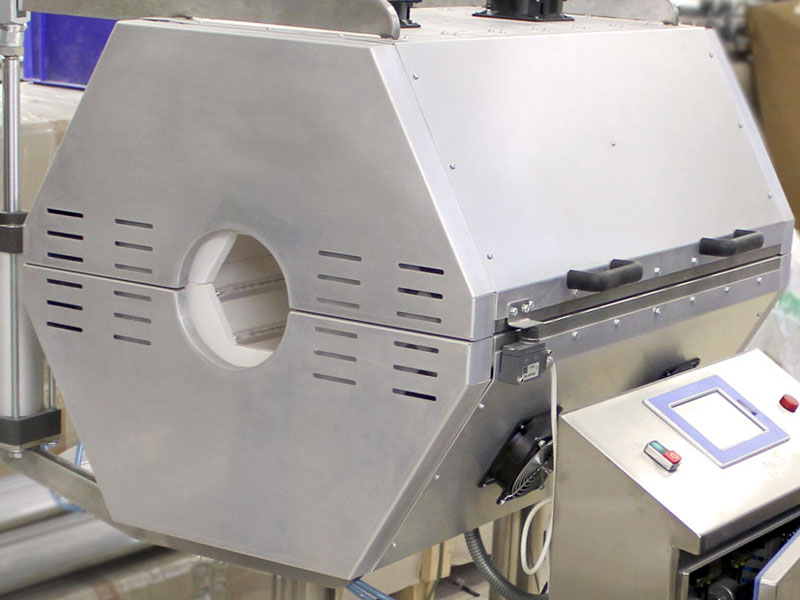

Clamshell Oven for Drinks Industry

Although clamshell ovens are a standard offering, this project showcased the power of innovation. By prioritizing efficiency, speed, and performance, WECO and Cermicx crafted a product that stands at the intersection of practicality and innovation. It is a valuable addition to any production process that requires the curing of synthetic materials.

Infrared Curing Oven For Speaker Foam

Finding the need to optimize production of their speaker line, a leading USA based consumer electronics company reached out to WECO International. The system was designed to cure foam on the back outer edge of polycarbonate speaker baskets at an accelerated time rate. Engineers designed a 42 kW infrared long-wave tunnel oven which was supplied in two sections.

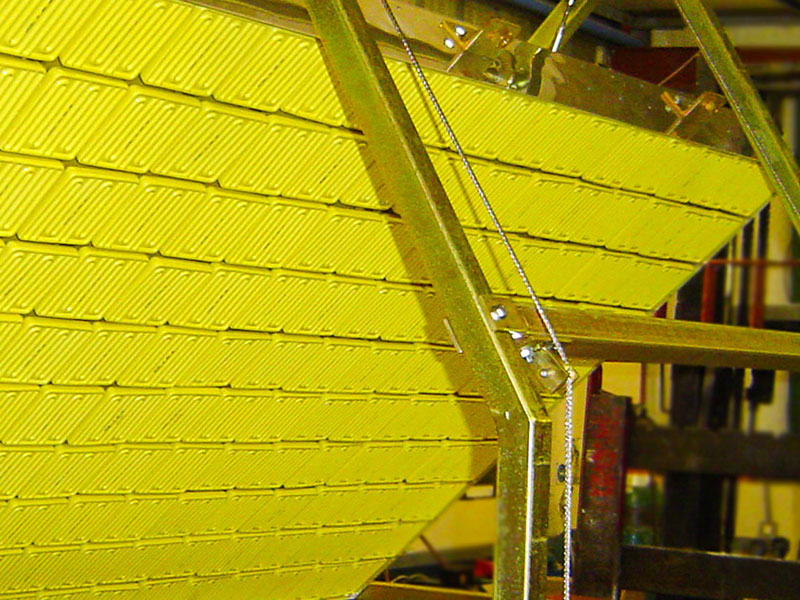

Preheat Polyethylene Film Before Embossing

A polyethylene film supplier sought to improve production and efficiency in preheating polyethylene film prior to embossing for food packaging. The key to the state-of-the-art machinery is the arrays of infrared ceramic, flat square hollow elements (SFEH). The new infrared heat system improved the start up times, line speed, and was a weight reduction on the installation.

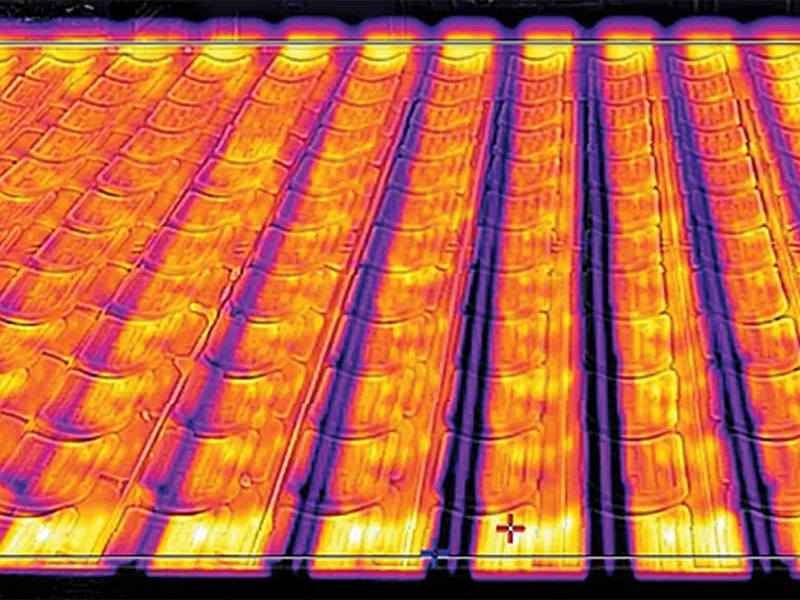

Thermoforming Heating System Upgrade

This client was struggling with an outdated and inconsistent thermoforming heating system. Ceramicx has the technology needed to provide the client with a new up-to-date system that can produce the same product every time while also improving quality and productivity.

Custom Industrial Furnace

The capacity to quickly test heat durability of new materials presented great advantage to our client. Not only does this ease innovation, the potential to expand into materials manufacturing for resale to third parties is now also readily available.

Custom Appliance Maker

A new platen system with zone-specific heating controls and energy smart technology was the best course of action to solve the issues at hand while giving the client the greatest options to hone production.

International Food Service Packaging Producer

The client required a complete upgrade on one of its main plastics thermoforming lines – manufacturing consumables for the food service industries.

Insulite Skylights Case Study

Santa Fe was in need for an upgrade an ageing and energy-costing plastics thermoforming line to an effective infrared based heating solution all while remaining well within the power constraints for the local electricity grid.