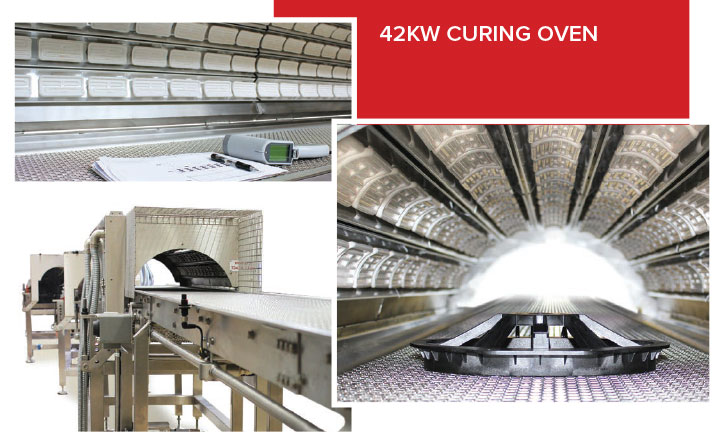

Beverage Manufacturing Innovation Using a Clamshell Oven

Supplier: WECO International + Ceramicx

Client: Beverage Company

Industry: Food Manufacturing

Location: USA

Innovative Solution to Cure Synthetics

In an era where industrial efficiency and innovation are paramount, we engineered a ground-breaking solution that has revolutionized the beverages industry – the Clamshell Oven. Always a great collaboration, this was designed by top-tier industrial heat consultants at WECO International and Ceramicx. The custom infrared oven has changed the game when it comes to curing the outer layer of a synthetic material utilized in the drinks industry.

360 Degrees of Rapid Infrared Heat

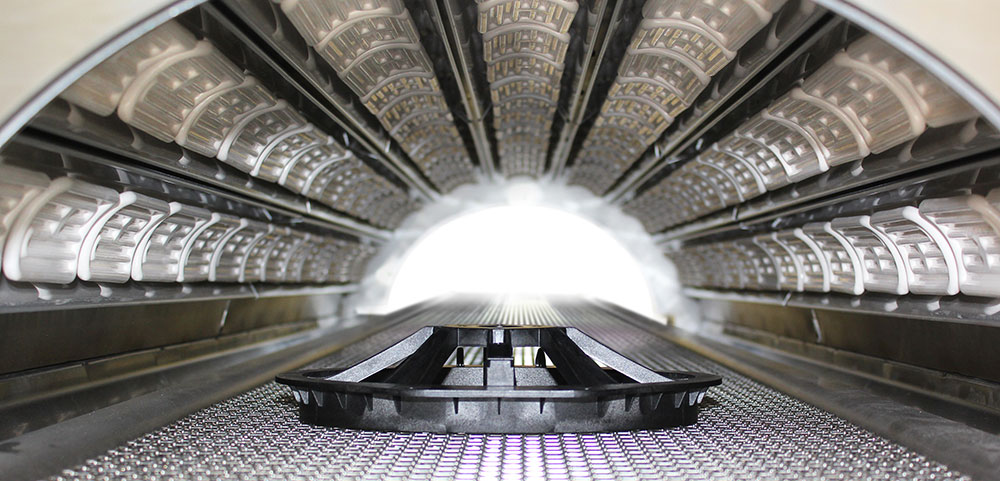

Our exploration of the Clamshell Oven underscores the transformative power of innovation. By prioritizing efficiency, speed, and performance, the creators of this oven have successfully crafted a product that stands at the intersection of practicality and innovation. A clamshell oven is a type of industrial oven. Specifically, it is is designed to provide uniform heating of the entire surface area of a product. The clamshell shape is ideal for curing the outside layer of a synthetic material used in the drinks industry1.

Multi-Zone Clamshell Infrared Oven

As we delve into the mechanics of the Clamshell Oven, it’s impossible to ignore the striking design that harkens to a clamshell, hence the name. The oven boasts of Quartz infrared heating elements which contribute to a more rapid heater response. This feature is particularly advantageous in systems with long heater off-cycles. As is standard for Ceramicx and WECO ovens, the frameworks of all components (infrared range and conveyor) were constructed with stainless steel.

Optimal Integrated Oven Controls

This 12 kW+ unit is controlled through an HMI interface using control hardware and software from Canon Automate and Cermicx. Now, you may be wondering about the internal mechanics. A well-designed ventilation system incorporating fans and ventilation slits ensures that the oven’s insulation and wiring stay cool, maximizing safety and efficiency.

Fast, Precise, High Heat from Quartz Halogen Elements

The clamshell oven has a total power of 12.1kW, a power supply of 3 x 400V + N + PE, and a maximum current/phase of 18A. It has a maximum operating temperature of 650°C (1292°F) and uses short-wave quartz halogen elements. The oven has three control zones, an open loop control type (with an optional single zone closed loop), and a touchscreen HMI power control interface. The temperature is measured using a single-type K thermocouple (measuring air temperature).

The footprint of the oven when closed is 1153 x 991mm (45.4” x 39”). And when open it is 1400 x 991mm (55.1” x 39”)1. The overall height from the floor is 1350mm (53.1”), with an oven length (entry to exit) of 991mm (39”) and an effective heated length of 740mm (29.1”)1. The entry/exit diameter is 150mm (5.9”), with a maximum product diameter of 100mm (3.9”)1.

In conclusion, the clamshell oven is an effective tool for curing the outside layer of synthetic materials used in the drinks industry. Its design allows for uniform heating, precise temperature control, and efficient operation. It is a valuable addition to any production process that requires the curing of synthetic materials.

Have further questions or a similar project? Your expertise is just a click away.