Bonding Automotive Interiors Using Infrared Heating Systems

Supplier: WECO International

Client: Tier 1 Automotive Supplier

Industry: Automotive Manufacturing

Location: North America

Opportunity:

One of the biggest US automotive companies sought a more automated solution to their production process. It is a fact that the world’s automotive industries continue to drive down production cost and increase user performance. Light-weight and stronger modern materials are enabling this evolution. Our expertise in these new manufacturing processes are driving that change.

Client Challenge:

Considerable ingenuity is often required to bring the pieces of a modern automotive car together. Techniques of welding, annealing, shaping and heat forming can all play their part – from the construction of the humblest hatchback to the top of the line luxury car.

The Tier 1 automotive supplier contacted WECO International. They wanted specifically an infrared heating system to bond leatherette materials to the interiors of automotive passenger doors for the cars that they were producing. The automobile doors had multiple parts, so they needed multiple heating systems for bonding automotive interiors.

Our Solution:

IR heat technology has several possible roles to play. It is used in the drying, bonding, and annealing of various automotive materials and components. As well as in the production of various automotive parts and structures. WECO International provides infrared drying, curing, adhesive and bonding solutions for automotive companies in all major materials including plastics, glass and metal. Therefore, there has also been an increase in call for our engineers to design and build drape forming and thermoforming ovens for the production of larger automotive parts.

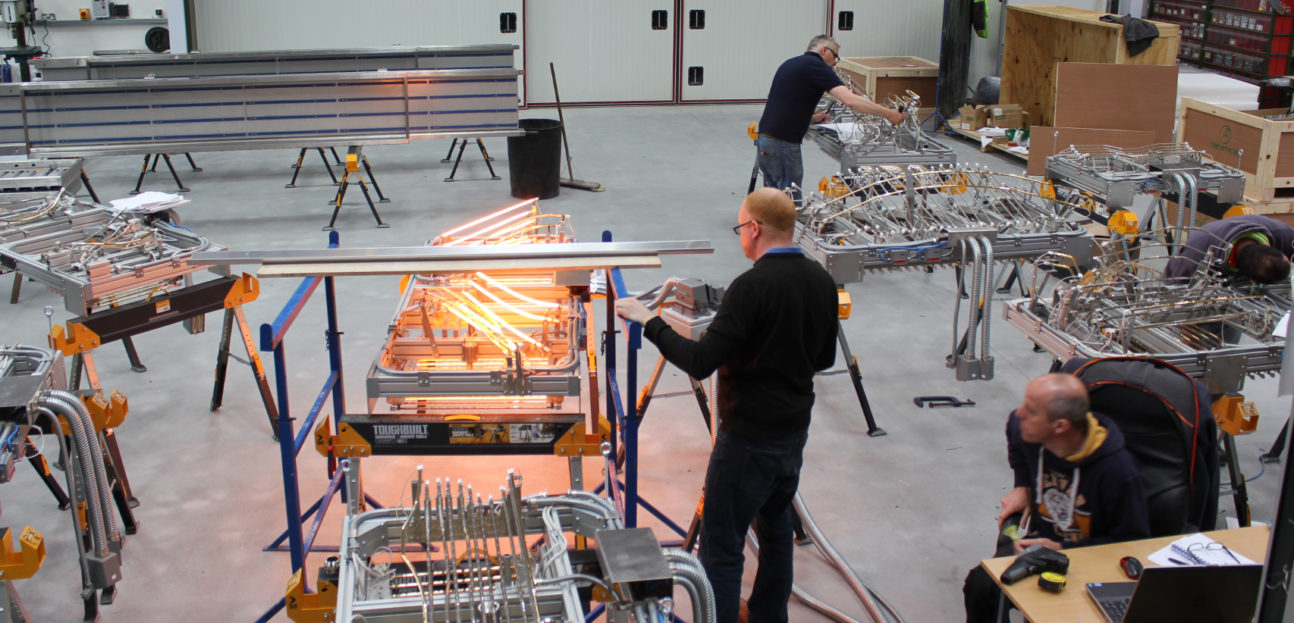

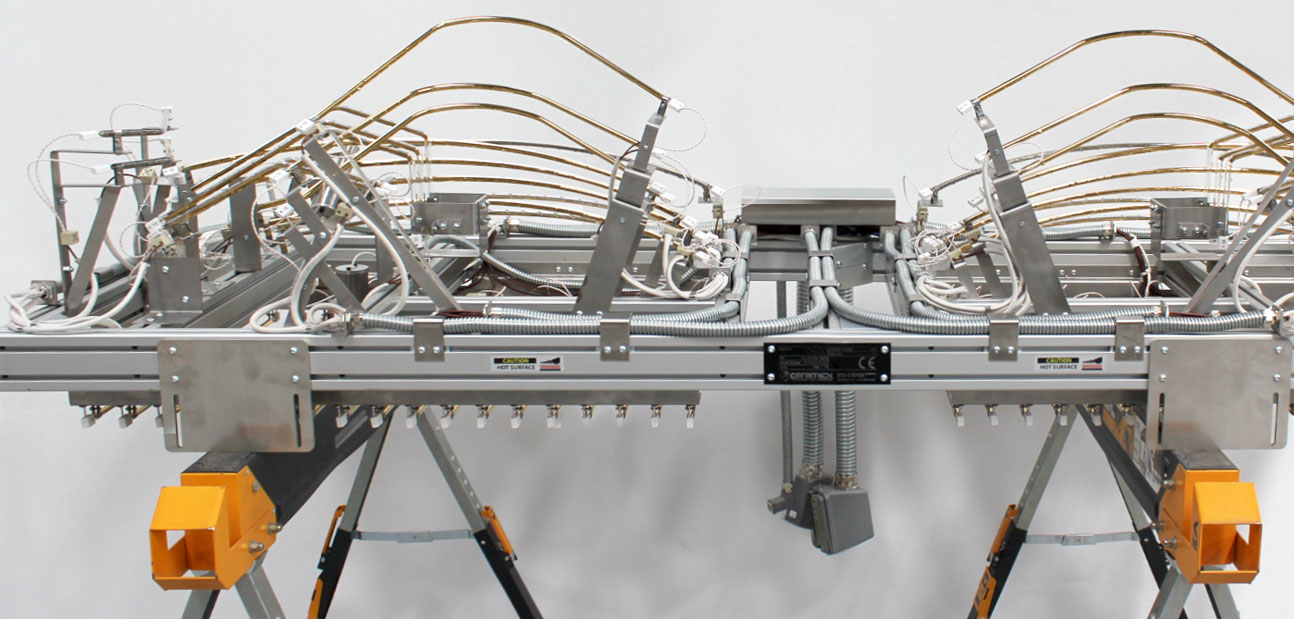

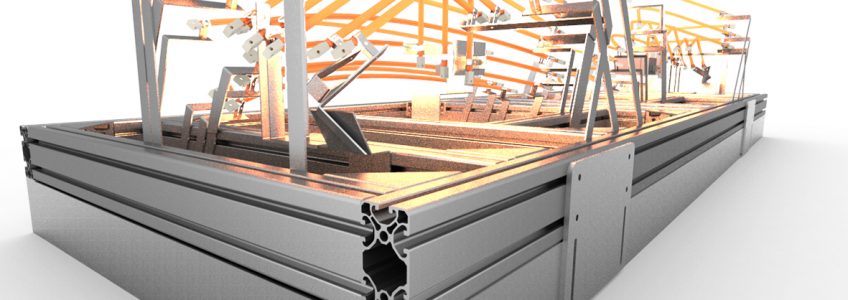

WECO International recently worked with their ceramic infrared heater manufacturer Cermicx to design and built the featured infrared heating system. The custom system is a perfect fit for the automotive thermoforming application. Together they designed a one-of-a-kind heating system consisting of 37 custom heaters. The process involves the heating of already formed parts with quartz tungsten tubes. There are 8 platens in total which all fit onto one machine as required by the client. The heaters face in both directions, up and down. The construction is made from aluminium profile. There are custom made stainless steel brackets holding bespoke shape and size heaters in place.

One frame has two banks of heaters. On the lower face of the frame there are straight tungsten heaters for heating of the leatherette fabric. The upper heaters are custom shaped heaters to exactly match the surface shape of the part being heated. Also, one control panel has also been supplied for all eight heater platens. The heaters are plugged into the panel as required and the HMI displays the correct platen and required information from the PLC program.

Outcome:

The system designed for bonding automotive interiors suited the intricate and exact shapes that the customer wanted. Subsequently, this ensured uniformity of heating over the entirety of the part. Together with Cermicx, WECO designed the custom fast medium-wave, Quartz Tungsten Tubes. This option suited the material that the customer was processing and ensured it was the most efficient way of heating the material. An additional benefit incorporated into these heaters was the incredible speed at which they reached temperature. Above all, this also minimized further loss of time for the customer. In total 8 different systems were built and all the systems fit in the one machine.

While specific details could not be provided, our client reported increases in both the quantity and quality of finished goods. The future challenges of automotive niche and smart manufacturing are met with process ingenuity at optimum cost.