Custom Industrial Furnace for Private Aerospace Company

Supplier: WECO International + Ceramicx

Client: Private Space & Aeronautics Company

Industry: Aerospace Manufacturing & Spaceflight

Opportunity:

A generation of dreamers and thinkers in the mid-20th century knew space to be the “final frontier”. The technology and means to venture beyond Earth’s atmosphere, though, were limited to government-funded endeavors. That is, until, very recently. Our client, a private aerospace industry manufacturing and spaceflight company, contacted WECO International, in tandem with Ceramicx, to create a custom industrial furnace capable of generating heating in excess of 2,000º F, replicating the conditions of atmospheric reentry in a controlled setting.

Client Challenge:

The reentry following orbit is the single most crucial part of any spaceflight. One error in piloting, failure of heat shielding materials or systems malfunction can be the difference between catastrophe and a successful mission. Our client pioneers innovative materials to protect an orbital module from extreme heat. Prior to our collaboration, the ability to test the efficiency and durability of those materials in-house was lacking. Before contacting WECO International, all experimental components had to be outsourced to a specialty-testing laboratory during the R&D phase. Outside materials proving firms were a large hurdle to minimizing cost barriers and production efficiency. As such, efficiency in these areas is vital to the client’s goals.

Beyond the involvement of large financial and time investments , the absence of a high-heat furnace of their own hindered research and development. The capacity to quickly test heat durability of new materials presented great advantage to our client. Not only does this ease innovation, the potential to expand into materials manufacturing for resale to third parties is now also readily available.

Our Solution:

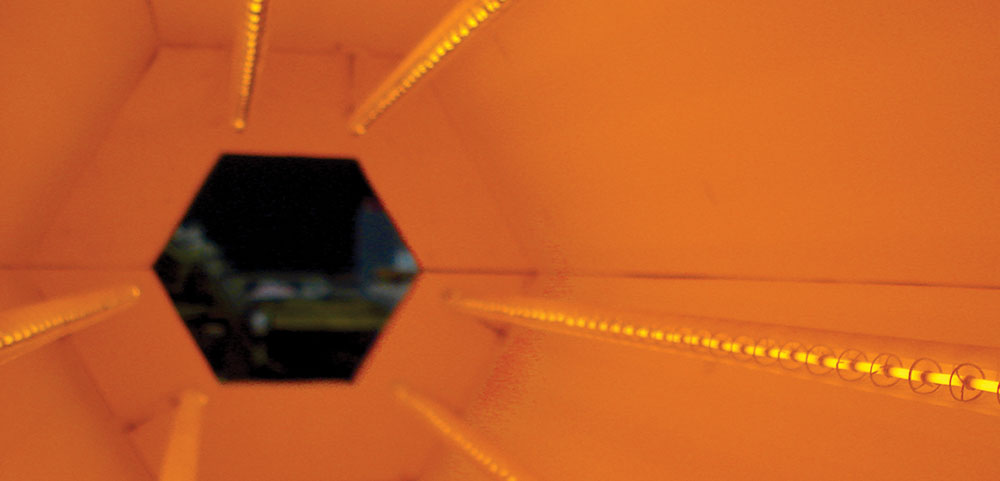

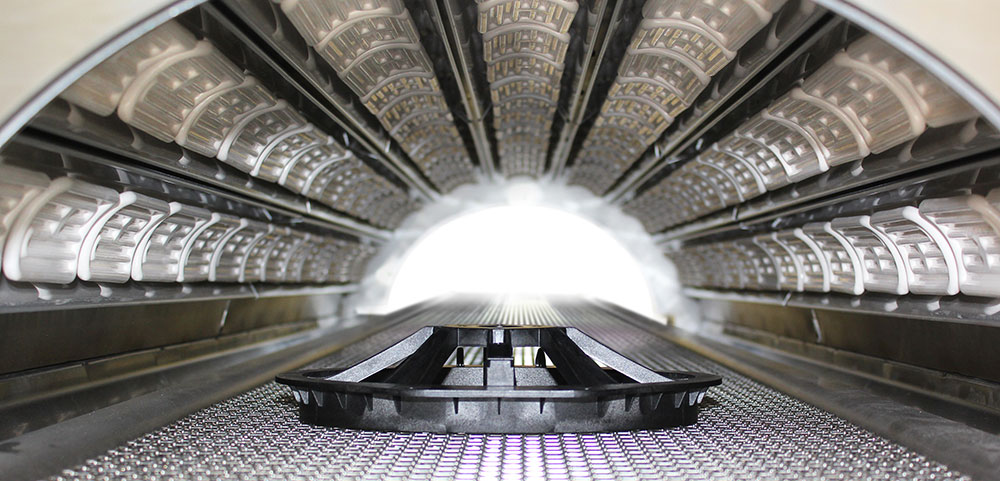

Projects of such extreme demands come very rarely. With that in mind, our experts collaborated with Ceramicx engineers to determine the most effective course of action. Over the course of many months, WECO International, together with Ceramicx, applied the needs of our client in creating and presenting custom furnace concepts for consideration. This high temperature oven is the hottest furnace made to-date by Ceramicx designers. Before final delivery, WECO programmed and tested the components to ensure furnace efficiency and total client satisfaction. At completion, a furnace lined with specially designed heating elements, two observation ports and matching specific heat control systems made its debut at our client’s facility.

Outcome:

As our client’s industry is highly-sensitive and specialized, specific details about the project remain in the highest of confidentiality. However, the R&D process of our client has greatly expanded. The capacity and diversity in terms of production has grown as well, while loss-leaders – chiefly transportation and time – have been diminished.